Embroidery

Sais Industry products almost always need personalized designs embroidered onto them to ensure their distinctive appearance and look. The method is a speedy and inexpensive means of decorating sports apparel, as it is faster than sewing or screen printing and also very versatile. Embroidery also works with various fabrics and threads to provide several different design options. We are pleased to serve as an embroidery provider at Sais Industry. If you order embroidered item decoration from us, your products can be embroidered on a wide variety of fabrics, such as t-shirts, t-shirts, polo shirts, sweatshirts, hoodies, pants, shorts, jeans, and more.

Regular Embroidery

The most practical technique for giving design to your products is regular Embroidery. Sais Industry changed the notch up when it began offering Embroidery in addition to screen printing or sublimation on one garment.

Regular Embroidery has allowed customers to produce brand-new concepts for their apparel. Regardless of whether you look at a particular promotional symbol and desire it to be embroidered and screen-printed simultaneously, there’s no need to look anywhere else than Sais Industry. All you need to do is send in your designs, and we will reveal the perfect option for your garment, depending on the fabric you pick.

Embroidery Patches

Embroidered patches can be easily and quickly stitched, with a high-quality result, and they cannot be placed directly on fabrics. There are several types of embroidered patches. Some are adhesive, while others are stitched, but they all serve the same purpose: to prevent the inside feeling of Embroidery when worn. Some people prefer Embroidery on patches to be applied to a customized garment to maximize the embroidery density.

When Embroidery is the essence of a design, people prefer embroidered patches rather than direct Embroidery on lightweight fabrics such as jerseys. This is due to the heaviness of the threads applied on top. With Sais Industry, you can order these patches in special design cuts and apply them in any way you choose.

3D Embroidery

Choosing raised or 3D Embroidery will create a more 3D-like effect and make your design more noticeable. Using this process, the design retains its thread-like appearance while wearing a puffy appearance. Regarding hoodies, sweatshirts, or other heavy fabrics like fleece or French terry, 3D Embroidery is one of the preferred options. This is because regular Embroidery on such fabrics results in the design not being as noticeable as it could be. Consequently, 3D Embroidery makes these types of fabrics more prominent.

Custom Embroidery

There are several things to consider when embroidering clothing, including thread breaks, irregular bobbins, thread tensions that are not appropriate, and bad framing, to name a few. These are all things that can make Embroidery a challenging task. We have gone through countless challenges over the years, and the hardships have taught our skilled workers to opt for best practices to ensure amazing results for our clients.

The company has gained extensive knowledge and expertise in a wide range of services. As one of the finest embroidery manufacturers, we offer many possibilities in terms of customizing and personalizing your products.

Quality Assurance

Our professionals always succeed in providing you with quality products when it comes to custom embroidery, and we guarantee you that our products are first-rate and excellent. In order to provide impeccable output, superb thread quality, and tight, even thread tension with the right balance, we utilize sharp needles and backing paper. Moreover, we ensure that your embroidered designs always stand out by using the correct bobbin length and tightness on your frame. Our Quality Assurance team rigorously checks the quality of our custom embroidered products. Every detail is maintained to ensure precise outputs are delivered to you. We use the industry’s most sophisticated software and machines to digitize your artwork and state-of-the-art technology to optimize your orders for the most optimal-possible results during the digitization process.

Fashion trends have evolved so much over the years that fabric processing has become an important element of any attire. Throughout the course of recent centuries, scientists have been able to discover a variety of different ways to make fabrics stronger, softer, more unique, and more comfortable because of modern-day revolutions. It has also been observed that many of these processing methods have evolved from just denim to 100% cotton and various blends of polyester and cotton.

Many people use different techniques to give their garments a vintage or classical look. Many of these techniques involve washing the fabrics with such chemicals and in such environments that make them stand out without compromising their reliability and longevity. We offers many options in this range, and there are options for doing multiple types of washing at a minimum order quantity starting at 50 pieces.

The process of Acid Washing, Enzyme Washing, and Burnout can be used to create an actual vintage clothing business where one may focus solely on vintage items or even include vintage items in an ordinary wardrobe collection. The use of silicone washing, bio-washing, and preshrunk washing allows people to address issues like shrinkage, wrinkles, and press with ease. It is objective to provide its customers with all the services they may require and work out the most appropriate solutions for each of them based on their requirements.

Preshrunk Washing

When woven or knitted, some fabrics tend to leave many open spaces between their bindings, which, when washed, causes the garment to shrink up a lot. We offer our customers the option of having the fabrics pre-shrunk so they can gain the proper grip on the garment. Once the garment has been pre-shrunk, it will become more tightly gripped and retain its shape as long as it is washed in either cold or hot water. Besides doing this, it’s also an effective way of expressing to your customers your concern for their clothes’ durability, especially if you sell them to people who wash their garments too frequently. When they buy a medium, it stays a medium even after they have washed it several times.

Silicon Washing

We can wash your customized garments by a process called silicon washing, which adds more softness and flexibility to the fabric. It also plays a role in a pre-shrink washing process, binding the knit edges of the fabric resulting in a more tight-fitting garment.

Your customer will be able to see your designed clothing garment in a new light, which makes him fall in love with it, and it will increase the life of your garment in such a way that even after three to four washes, it will still be as soft and new as the first day it was worn. Silicon washing is designed to make the garment softer, more comfortable, and more durable

Bio Washing

We also offers the option of applying Bio Washing to your garments, a process that not only adds softness but also gives them an extra shine once they have been washed. This process is a highly effective method to maintain and preserve the color and quality of your custom-made clothing garments at a higher level for a longer period of time. Natural soap suds, color fixers, brightening agents, and cloth conditioners make it a great alternative to detergents that contain harmful chemicals.

Acid Washing

Our team also offers acid washing, also called stone washing, to give your clothes that much-hyped fade effect. You can choose to have it done the way you like. We usually do this on garments made from stronger fabrics like denim and twill. If you’d like to try this process on any other fabric you’d like, we’d be happy to do it. Cotton jersey fabrics do best when acid washed, as it gives t-shirts and anything else made of cotton a vintage look.

Enzyme Washing

In addition to enzyme washing, we offers you the option of polishing your customized fashion garment, increasing its color fastness and rubbing fastness. Attacking more of the fabric surface improves the garment’s anti-pilling properties, resulting in a smoother surface.

It is possible to use acid enzyme washing or neutral enzyme washing at our facility, each of which has its own specific uses for enhancing the appearance of your clothing. We recommends that you opt for Enzyme Washing so that your product can offer you multiple benefits that can be used while selling your garment.

Sais Industry is a PK-based clothing Manufacturer of sports apparel that uses various printing methods to create custom designs and logos. Printing techniques include direct-to-garment, heat transfer, screen printing, digital printing, and sublimation. Each printing method is better suited to specific apparel items due to its strengths and weaknesses. For example, T-shirts are often printed with logos and designs using direct-to-garment printing.

The special ink is used to print images directly onto the fabric. Vibrant colors and a durable finish are the benefits of this process. Printing takes just a few minutes, making it one of the fastest methods. Heat transfer printing is used to transfer pre-printed designs onto apparel items. Sports brands can use this method to create intricate logos and graphics that last longer than direct-to-garment printing. In addition, it allows more control since the graphic can be placed precisely where it is needed.

In contrast, screen printing is often used to print large quantities of a single design. In addition to being cost-effective, it offers various colors and finishing options. In addition to creating unique and eye-catching designs, digital printing is also suitable for creating full-color images and graphics. However, it can be quite expensive for large orders.

In addition, sublimation printing produces vibrant colors with a permanent finish. This method best suits fabrics made of polyester or polyester blends and requires special inks. Sports apparel manufacturers must ensure that the logos, graphics, and designs created for sports brands meet their high quality and durability standards, regardless of the method used. They can achieve the most effective results every time by selecting the suitable printing method.

Dyeing Process

Fortunately, you have come to the right place if you are looking for reliable clothing dye manufacturers. Sais Industry takes extreme measures to ensure that the goods we supply are accurate. Therefore, working with us as a supplier guarantees high accuracy. To achieve the most desirable results for our customers, we incorporate the latest technology and machines related to the garment dyeing. These include drum type dyers, paddle dying devices, and jet circulation. Furthermore, with our professional dyeing service, we have come across many different tests through which we have been able to confirm whether dyed colors on fabric can withstand regular use in various circumstances. Our in-house testing procedures include crocking, detergent washing, light and perspiration testing, and tests on color fastening before shipment. Efforts are made to meet every single one of your requirements, including finding a solution to any pain points you may have.

Direct Color Dye

Finding the right color for your clothing line can take a lot of work, especially when low minimum orders limit you. The only alternative is to choose a solid color fabric that is readily available to you, but we offer a unique option. By choosing the direct color dye option, you can have a specific color for your garment without worrying about what shade you have. In order to accomplish this process, Sais Industry offers customers the option of providing specific Pantone codes. This will ensure that the colors of the apparel can be precisely matched to eliminate any errors. If you need a minimum of 100 garments, this is the most suitable option for you, as it can be done for any number of garments you need. There are some advantages and disadvantages that come with direct color dyeing. There is no better benefit than getting the desired color for a lower minimum price. Reactively dyeing fabric may have less fine detail than direct dyeing. However, this is a fantastic option if you are almost only concerned with the color.

Reactive Dye

Reactive colors are highly durable. No matter how often they are washed or exposed to sunlight, they don’t fade away. Getting a custom color on your garment is one of the best ways to ensure that it will have a premium feel, as it enables you to get a custom color on it. It is possible to dye a fabric reactively when it is knitted from the start in an exact blend that meets your needs. The advantage of this is that customers will be able to purchase larger quantities without having to worry about quality or colors. Regarding the production of customized garments, factories worldwide follow this process in an industrial setting when there is a high quantity involved. Our reactive color dyeing service is available for a low minimum of 800 pieces.

Tie Dye

We would be pleased to work with you on custom tie-dye designs. You can even send us a picture of your design. We would love to match your fabric in a similar way to what you are looking for, even if there is just a small quantity. The Tie Dye technique may only be used on 100% cotton garments. Fortunately, cotton is one of the most popular fabrics all around the world due to its soft and pleasant feel, as well as its lasting quality. The garment can also be bio-washed after dyeing with reactive colors for long-lasting performance and a nice feel. We welcome your designs regardless of their form or if you make your own. Customers thinking outside the box are always welcome to speak with our business developers to ensure their ideas are balanced from all angles.

Dip Dye

When a customer wants to have more than one or two shades of a garment, we can do dip dyeing on your garments with reactive colors; we can make them more customized by doing after processes on them so that your garments look more just the way you want them to look, so they are more comfortable to wear.

When the pattern is simple, like when you’re doing tie dye, this can be another way to give your garments a multi-color look with a multi-color pattern. As a clothing manufacturer, Sais Industry is well aware of its responsibility to provide almost all customization options at the lowest quantities starting from just 50 pieces per color and design for every item.

Neon Dyeing

You can dye your garments with neon dyeing to give them a glow in the dark. We use neon dyeing to dye your garments by adding neon glow to them using chemicals. You may also choose to mix things up by adding glow-in-the-dark printing that we do on your garments. Regarding customization, there is no limit to what can be done with this method.

Ultimately, the choice you make is whether you want to keep up with the changing market trends or if you want to do the kind of customization that everyone else offers. It is entirely up to you. Full liberty is given to customers to fulfil all dyeing needs, including Neon.

Yarn Dyeing

With yarn dyeing, you are able to create fabrics with already dyed yarns. Garments made from these yarns look like multicolored fabrics with lines. You can also get whatever color continuity you want for your customized garment. This is mainly used for making garments that look more like multicolor fabric.

There must be at least 1500 units of the end product produced in order for it to meet the minimum quantity of machinery necessary to create the fabric. Therefore, there must be a minimum quantity.

By choosing to dye your own cloth, you can be assured that you will be able to get the perfectly dyed polo that you have been dreaming about. You can also go for a golf shirt that has been dyed using yarn as an alternative to a conventional golf shirt. With this dyeing process, there are no limits to how you can make garments.

Our goal at Sais Industry is to accommodate all the types and varieties of private-label clothing needs our customers may have. As a result of our significant experience in private label manufacturing, we can also back up our expertise with a range of customization services in addition to manufacturing high-quality blank products. Among our customers, we have private labels from all over the world.

The custom cut and sew manufacturing services we provide are of the highest quality. The advantage of this service is that we not only purchase fabric that perfectly suits your requirements, but we also offer complete manufacturing services. This will lead to your finished product. Therefore, we can handle the entire fabrication process from start to finish. This is not only for the desired products but also for delivering the final product right to your doorstep.

High-Quality Private

Label Clothing

Sais Industry is one of the finest suppliers of private label clothing in the USA. Whatever your needs may be, we’re always here to help you find the right solution to your problems, no matter your requirements. We offer private label luxury clothing and fantastic customization services for your products that can enhance your brand image and keep your products on top of your customers’ minds. With white label clothing manufacturers, you can find a wide variety of high-quality private label clothing with hang tags in any size and shape you need. This also includes a wide range of private woven labels, private satin labels, and heat transfer labels made to order. Nothing is impossible for us when it comes to clothing manufacturing.

Custom Woven

Labels

For clothing brands and retailers, the use of woven labels as a way of displaying information about their brands and products is quite common. It contains information about the brand, its logo, and the product size. Weaved labels are a great way to provide your clothing with an elegant touch and make it stand out from the rest. At Sais Industry, the minimum order quantity is 500 woven labels. As part of our service, we make woven labels for your garments and stitch them to them without charging a stitching fee. The labels can be attached to your clothing, neck, or anywhere else you wish to put them.

Custom Satin Labels

Private-label clothing is very popular these days because of the softness of the satin label. Especially when it comes to clothing like personal label t-shirts that are worn in close proximity to the skin, it is an ideal choice. Our minimum production quantity at Sais Industry is 500 pieces. With the right custom clothing manufacturers, you can have all the facilities in terms of apparel customization for your brand. This label is available in several colors, including white, black, cream, and gray. Depending on the font size, you can print branding information, a logo, or a size using one or two different ink colors. In order to customize your label in any way you like, you can choose the material color, ink color, font size, style, and label size.

Custom Hang Tags

If you are hanging your garments in a store surrounded by thousands of other clothes, a hang tag is a helpful marketing tool. This is because it grabs the attention of potential customers.To market your garments more effectively, you can customize your hang tags with us; we will do all the work under one roof so that you have more control. The hanging tags we offer are in any shape and size and have punched holes and string attached so that they can be used easily. For hang tags, there is a minimum order quantity of 500 pieces. Moreover, we kept these instructions with us so that you can refer to them in the future if you need them.

Heat Transfer

Printed Labels

Many small clothing brands are looking for labels that can be heat pasted. In addition to showing off your perfectly designed apparel, a heat transfer label is a great way to show off your ownership of it. This is a new way of comfortably providing tag-free branding information while also providing useful information. For instance, if you are running a t shirt clothing brand, the heat transfer printed labels can turn out to be very useful for you since the first glance of customers falls directly on what shirt one is wearing. We, as a top-rated t shirt manufacturer can offer you all the customization plus heat transfer printed labels for the unique identity of your brand. It is usually advisable to paste heat transfer labels inside the neck area of a garment. Our minimum production requirement for heat transfer label stickers is 1000 pieces.

Printing Method

Sais Industry is a PK-based clothing Manufacturer of sports apparel that uses various printing methods to create custom designs and logos. Printing techniques include direct-to-garment, heat transfer, screen printing, digital printing, and sublimation. Each printing method is better suited to specific apparel items due to its strengths and weaknesses. For example, T-shirts are often printed with logos and designs using direct-to-garment printing.

The special ink is used to print images directly onto the fabric. Vibrant colors and a durable finish are the benefits of this process. Printing takes just a few minutes, making it one of the fastest methods. Heat transfer printing is used to transfer pre-printed designs onto apparel items. Sports brands can use this method to create intricate logos and graphics that last longer than direct-to-garment printing.

In addition, it allows more control since the graphic can be placed precisely where it is needed. In contrast, screen printing is often used to print large quantities of a single design. In addition to being cost-effective, it offers various colors and finishing options. In addition to creating unique and eye-catching designs, digital printing is also suitable for creating full-color images and graphics. However, it can be quite expensive for large orders.

In addition, sublimation printing produces vibrant colors with a permanent finish. This method best suits fabrics made of polyester or polyester blends and requires special inks. Sports apparel manufacturers must ensure that the logos, graphics, and designs created for sports brands meet their high quality and durability standards, regardless of the method used. They can achieve the most effective results every time by selecting the suitable printing method.

Silk Screen Print

Silkscreen printing is among many ways to print designs onto an item. Due to its cloth-friendly nature, it is able to print solid-color designs onto just about anything, no matter the blend or processing of that material. Sais Industry employs negative ink to create a few of the designs in their pieces rather than using paper; this results in sharper photos.

The best place for our printing method is that we are open to more than certain machines for printing complex designs. This allows for the best result in terms of coverage and matching colors.

Flock Screen Printing

Synthetic fibers such as cotton, rayon, and polyester are the primary basis for the flock. After applying an adhesive liquid to the designated geographical area, the flock is applied to it.

Flock screen printing has an embossed and smooth texture. To get different colors, the first flock-colored dye is used for the base, then it’s layered on top of the adhesive coating given a screen. The result is a delicate velvety softness.

Water Based/Pigment

Screen Printing

Due to the water-based price of the color, pigment screen printing, also known as water-based screen printing, is a lot like discharge screen printing. Still, the resemblance is that the color is impacted by water-based instead of Plastisol-based liquids or liquids. This technique is primarily employed on white and light-colored fabrics.

Discharge Screen Print

All machinery has remained the same for the discharge screen printing technique, but the inks used differ. Discharge inks are actually used for the method of printing onto shirts. When transferred to shirt material, these inks damage the original color and replace it with the applied color. The surface acts like cloth when it touches, providing a soft feeling. Discharge ink can be used as a standalone printing medium or to base another ink. It’s similar to water-based printing that’s usually done on darker fabrics. High Density (3D Printing) Sais Industry offers high-quality printing services. Along with that, the professionals guide the brands regarding the accurate ways of utilizing the techniques. High-quality and high-definition printing are akin to puff printing, but that’s true only in concept. A soft character and imperfect printed edges generally characterize puff printing. The viscosity of inks used for high-density printing allows them to slip through screens without adhering to them, so screens yield sharper and fine edges.

But vivid hand-painted light effects give them a 3D look as well. This is where the shape quality of high-density printing comes in. Puffy inks for high-density printing create smooth, sharp edges but add a little extra puff. It is not recommended to wash high-grade prints frequently due to the high quality of paper material used. However, it could be useful to iron them on substances that do not have sufficient washing.

Digital Printing

Digital printing is a valuable part of sports apparel manufacturing because it provides a highly efficient method of producing sportswear for individual athletes, teams, and clubs. Digital printing uses modern technology to create designs directly from computer files, dramatically reducing print costs and delivery times. Many clothing companies use digital printing to imprint high-resolution pictures on the fabric. The resulting garment is lightweight and comfortable, but it is also durable and made to withstand strenuous activity. Compared to sticker heat transfer printing, Sais Industry offers a safer alternative, is much more reliable and has a lower removal rate than heat transfer printing. As with stickers, this print produces a similar effect to a sticker, but it has a long-lasting effect and can be used to print real-life images on the product.

Glow in the Dark Printing

Glow-in-the-dark printing follows the same steps as normal printing. The only difference is that glow-in-the-dark ink is used. For glow-in-the-dark printing, special neon inks are used. These inks are typically used to highlight images.

This kind of glowing image gives better results on fabrics with darker textures. This printing technique is used for funky and cool images that convey a sense of style. If you want to create a themed clothing line, the shirt glows best at night when there is no light.

Puff Screen Printing

It uses specialized puff inks for screen printing t-shirts, sweatshirts, or jackets to give them a vintage appearance. Puff printing, on the other hand, uses specialized puff inks on screens. This technique is prevalent and is currently being applied to add a vintage look to t-shirts, sweatshirts, or jackets. A puff printing process uses specialized puff printing inks on screens. Heat is applied to the image after ample ink has been transferred to achieve the puff effect. Images may require pure puffs, and some require Plastisol as an additive to enhance their shine. Despite the fact that puff screen printing seems to be raised, in reality, it is a puff containing mostly air in between. Consequently, a larger puff increases the risk of cracking the print.

Direct to Film

(DTF) Printing

T-shirts, sports apparel, uniforms, and other items can be printed using Direct to Film Printing (DTF). Sports apparel is a perfect application for this method since it is a quick, easy way to print high-quality prints that won’t fade or peel, and can last for years. In the process, the image is placed on a film which is then exposed to a special light source. The film is then developed and adhered directly to the fabric. It is faster and easier than other printing methods, so it is the fastest and most responsive to time-sensitive print jobs. This method also increases the consistency of print quality, enhancing printed materials’ visibility and durability. Direct-to-film printing also provides prints with outstanding durability and better resistance to fading.

Direct To Garment (DTG)

Due to its industrial utilization and high cost, DTG is one of the easiest and best ways to print, but it also has a higher minimum requirement.

In addition, Sais Industry provides the best possible quality print for a minimum order of only 100 pieces. Sais Industry mission is to elevate clothing brands with its Direct to Garment printing services.

We believe that presentation is vital and that modern packaging trends are essential. Therefore, Sais Industry offers our customers a wide range of packaging options. Today, people are increasingly choosing biodegradable bags, and we understand the importance of nature in everything we do.

Sais Industry offers polybags and the option of incorporating biodegradable bags into your packaging to make it more environmentally friendly. In order to maximize the presentation options for clothing brand startups and existing brands, a custom clothing manufacturer must offer these types of packaging to them.

For customers who seek the most attractive presentation, Sais Industry offers polybags in several weights, twill bags, cloth bags, biodegradable bags, and paper bags. For a truly unique and prestigious brand, you can print custom designs on those packaging options.

Custom Poly Bags

Sais Industry offers custom packaging to customers. The most common way is through using polybag packaging. Custom polybags are an important tool for Sports apparel brands to protect and promote their products. They are an effective way to store and transport products from the factory to the point of sale.

As well as providing extra protection from wear and tear, they enhance the brand’s visibility by displaying logos and slogans on the outside, increasing its visibility. As a promotional item, custom polybags can be filled with product samples or offered for free by the brand, building brand awareness and loyalty through the use of promotional items.

The bags also serve as excellent packaging options for online shopping, the bags are also easily shipped and recyclable. Ultimately, custom polybags are highly effective marketing and promotion tools for Sports apparel brands.

Your clothing brand customers would appreciate something that is presented directly to them. We pack them in simple polybags. You can choose to have them packed individually or by the dozen. Aside from printing your logo on any polybag, you can make the plastic translucent or increase its quality. Over the years, Sais Industry has provided its customers with many packaging solutions that have improved sales for clothing brands.

Custom Fabric Bags

It is up to you how much quality product you want. Thus, if you want to add something to your brand that will give it a premium feel, a fabric bag would be a good place to start. As a result, you will offer your consumers the option of checking the fabric quality before they open your products. In addition, you will be able to give your garment a distinct appearance at the presentation time.

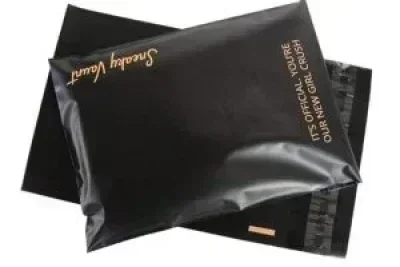

Custom Polymailers

We offer an array of options for poly-mailers if you are tired of the ones your courier company offers. In addition to custom poly-mailers, we can also offer you custom poly-mailer printing, so you can ensure your garment is safely packaged in your own poly-mailer and that it is of higher quality than other poly-mailers, which adds the additional value of marketing your brand name when you send it out.